ARE YOU ABOUT TO EMBARK ON A LEAN JOURNEY FOR YOUR NEXT MAJOR CAPITAL PROJECT?

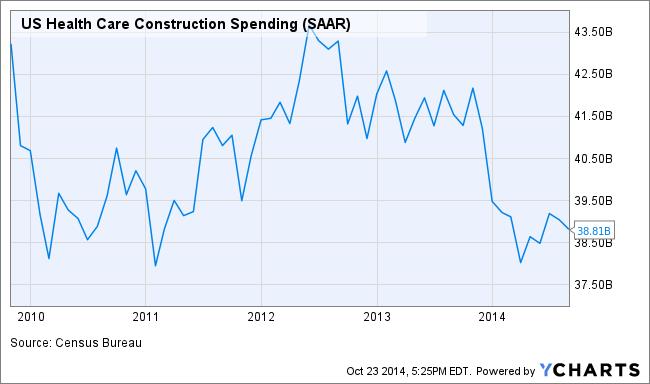

With over $38 billion spent on healthcare construction this year in the U.S alone, there is a tremendous opportunity for capital projects to incorporate efficiency, safety, and patient-centered care well before the first shovel strikes the ground. Healthcare clients, under extreme pressure to reduce costs,  desperately needed a new paradigm and in response, Lean Led Design practices have emerged. This new way of thinking requires healthcare organizations to evaluate work flow and processes, identify opportunities to remove non-value added waste, and drive bottom-line results prior to major capital spending. Nationally, healthcare clients and project teams are embracing Lean Principles which were originally developed for manufacturing. In addition, they are adopting Lean Led Design practices and integrating continuous process improvement teams to help reduce costs, address staffing shortages, and most importantly, increase the organization’s ability to see more patients.

desperately needed a new paradigm and in response, Lean Led Design practices have emerged. This new way of thinking requires healthcare organizations to evaluate work flow and processes, identify opportunities to remove non-value added waste, and drive bottom-line results prior to major capital spending. Nationally, healthcare clients and project teams are embracing Lean Principles which were originally developed for manufacturing. In addition, they are adopting Lean Led Design practices and integrating continuous process improvement teams to help reduce costs, address staffing shortages, and most importantly, increase the organization’s ability to see more patients.

BEGINNING A LEAN JOURNEY

The requisite for every project team engaged in a lean journey is to create a safe environment where high quality care can be delivered efficiently to achieve the best possible outcomes. Project teams must engage front line staff to help identify operational waste, consider alternative ways to do the work, and together develop design recommendations and guardrails for the capital project. Before the first deep dive into finding non-value waste or discussing seven ways to do  the same task, healthcare owners and project teams must understand the construction timeline, budget constraints and other key project guardrails to set the project parameters and milestones for the team. With end dates in mind, the project team can define how lean should be integrated into the facility planning and design process and determine if a Lean Led Design approach makes the most sense.

the same task, healthcare owners and project teams must understand the construction timeline, budget constraints and other key project guardrails to set the project parameters and milestones for the team. With end dates in mind, the project team can define how lean should be integrated into the facility planning and design process and determine if a Lean Led Design approach makes the most sense.

Not all projects afford teams a lengthy lean journey. The challenge for most capital projects is speed to market. The time it takes to design, construct and occupy varies for every project and must be carefully considered when deciding on whether to integrate process improvement efforts into the design schedule. The window of opportunity to contemplate process changes or new models for an improved future state in the new space must be defined and may not afford a traditional design approach.

LEAN LED DESIGN

and how the care is being delivered and how to quickly identify process waste that doesn’t bring value to the patient or the organization. Design teams work closely with staff to understand the role the environment plays in implementing many of the suggested operational improvements and begin to develop conceptual design solutions as well as programmatic and functional space requirements. When considering new ideas, Lean principles guide the entire project team to always keep patients at the front and center of the process and never lose sight of what is best for the patient.

and how the care is being delivered and how to quickly identify process waste that doesn’t bring value to the patient or the organization. Design teams work closely with staff to understand the role the environment plays in implementing many of the suggested operational improvements and begin to develop conceptual design solutions as well as programmatic and functional space requirements. When considering new ideas, Lean principles guide the entire project team to always keep patients at the front and center of the process and never lose sight of what is best for the patient. Lean Led Design is a collaborative approach and affords healthcare organizations to quickly identify many process improvements that may not have surfaced in a traditional department user group meeting. 3P Lean Events, which stands for product (patient care), process and preparation, is based on the Toyota production process and engages end users closest to the work along with the entire project planning team.

The project architects and engineers, the construction management team, and hospital leadership join the clinical teams and support staff in a vetting process of ideas. Many ideas are weeded out due to lack of support by others involved, limited resources, cost and implementation issues. The approach pushes teams to gain organizational support for process changes and collectively recommend those that would yield the greatest cost savings or best outcomes. This doesn’t always happen in traditional departmental level user group meetings where clinical teams mostly focus on the process that occurs within their immediate departmental boundaries and rarely have the opportunity to discuss the entire process with leadership, support staff, and other departmental teams.

By understanding the baseline and identifying reasonable future state targets that are measurable, healthcare owners and project teams can assess if the new approaches developed during 3P Lean Events truly improve quality and performance and reduce cost. 3P Lean Events fully integrate process design, functional space programming, and healthcare planning into a series of two and three dimensional modeling exercises that enables stakeholders to work out design details at a room by room level while keeping a broader focus on departmental adjacencies, intra-departmental connections and system wide opportunities and savings. During many events, several process improvements are identified that could be implemented immediately into existing space rather than waiting for the new project to implement. Organizations are afforded more time to perfect the new process prior to moving into a new space.

LEAN PRINCIPLES

The Lean principles that guide project teams during Lean Events were borrowed from manufacturing and include:

- Value: Only the healthcare consumer can determine value. Unnecessary tests or lengthy wait times do not add value to the patient experience and these activities represent non-value added waste. Neither a physician nor CEO can determine value, but they can drive value

when focused on the needs of the community and healthcare consumer. There is also a constant balancing act in healthcare process design between the optimal patient experience and an optimal work environment. During Lean events, it is important to engage focus groups or have someone consistently be the voice of the patient to help drive balance between work place preferences that override patient experience.

when focused on the needs of the community and healthcare consumer. There is also a constant balancing act in healthcare process design between the optimal patient experience and an optimal work environment. During Lean events, it is important to engage focus groups or have someone consistently be the voice of the patient to help drive balance between work place preferences that override patient experience. -

Value Stream: The value stream describes the sequence of activities for a healthcare service or process that produces value. For example, an admissions process where a patient provides personal information once and caregivers have the medical history readily available from a preadmissions process streamlines the time it takes the patient to arrive, receive a barcoded wristband and receive healthcare services.

-

Flow: Optimal Flow is created when non-value added activities are removed from the value stream.

-

Pull: The “pull” means the healthcare system only provides a service or product when the consumer signals the need. A great example of pull is in healthcare organizations that implemented par levels systems, like Omnicells or Pyxis machines, to track medications and materials per consumer. For environmental services, pull means the service of collecting soiled linens. Rather than collect linens a few times a day, which is a great example of batching work, a linen chute could be installed so soiled linens move immediately off the inpatient unit and are available for processing.

-

Perfection: The principle is to always strive for perfection in all value streams and to remember, perfection should always be considered from the perspective of the healthcare consumer.

PROCESS WASTE

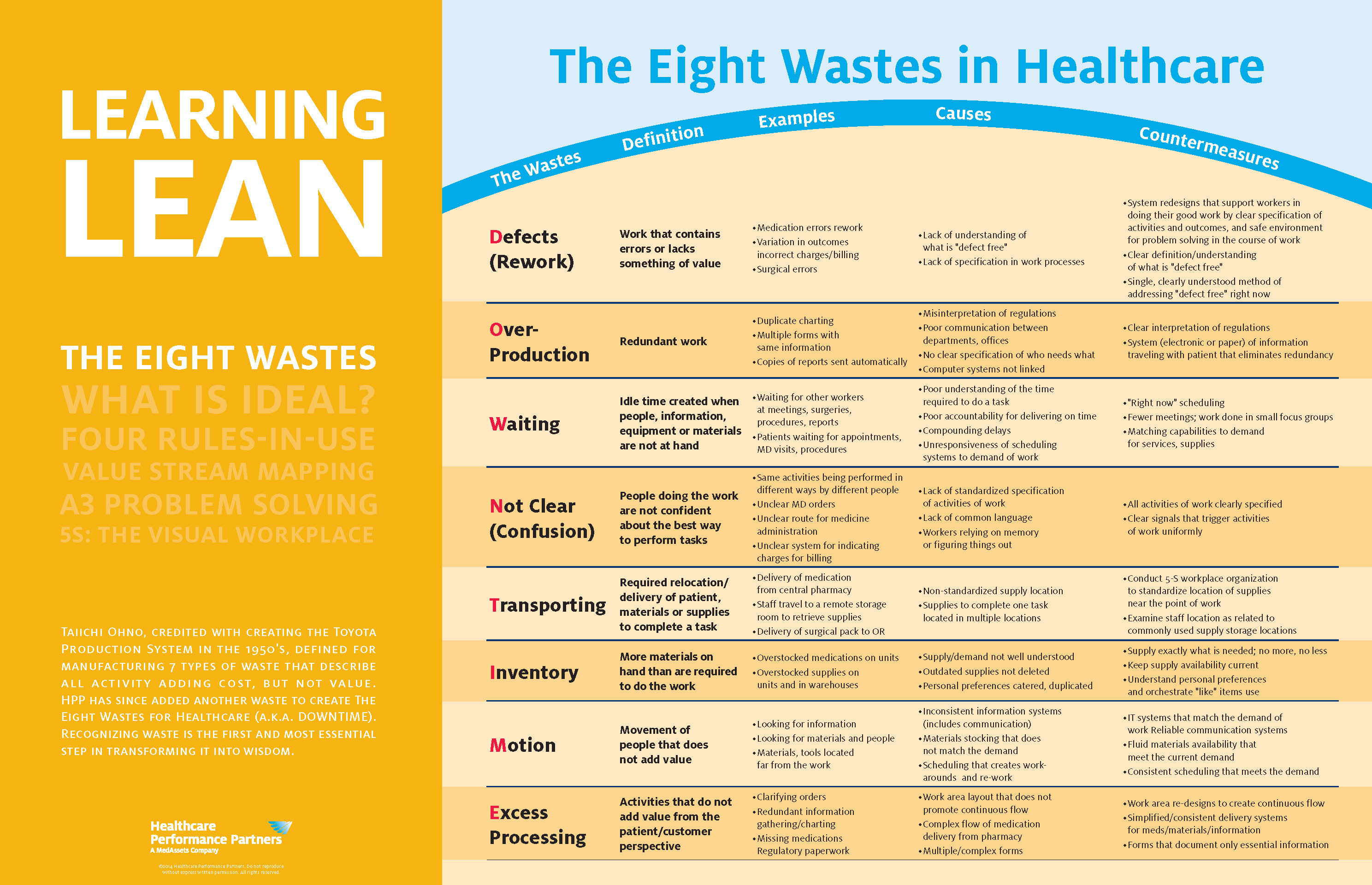

In healthcare facilities, there are eight areas of process waste typically discussed in a 3P Lean Event: overproduction; waiting; inefficient conveyance; rework; excess inventory; unnecessary motion, such as over long walking distances for nursing staff or excessive patient transport; and correction, or steps undertaken to remedy situations caused by wasteful practices. Figure 2 defines and identifies waste areas and provides examples that the project team can discuss. Understanding the root cause of the waste will help teams better address alternative options and assess if the countermeasure will rid the waste and non-value add from the process.

(Image credit Healthcare Performance Partners; copyright Healthcare Performance Partners, Inc., used with permission.)

CONCLUSION

Are you about to embark on a Lean journey for your next major capital project? Healthcare owners should understand the initial investment of staff resources required to conduct Lean Led Design events and how important it is that leadership remains engaged in the process. Continuous process improvement teams and leadership must be willing to embrace change and do what it takes to implement it. Consider outside resources to help train staff in Lean Led Design, facilitate 3P Lean Led Design events, and assist in transforming organizational culture towards a future state that consistently seeks to improve operations, improve quality, be more patient centered, and reduce healthcare costs.

Lora Schwartz, Principal Consultant, CBRE Healthcare